Our Services

To get started with SisuSemi’s solution we have three basic proposal to help you to find the value.

All of those follow the same basic engagement model shown in below.

Three Basic Proposals

Fast and simple – Components

- Treat components to compare performance before and after treatment.

- Improve interfaces, unlocking 10% to 40% of potential.

- KPI: Leakage current.

- Proposed sample amount: 12 chips.

In-Depth – Surface quality

- Analyze wafer surface quality and composition.

- Improve surface quality at the atomic level.

- KPIs: Defects, contaminants, surface structure.

- Proposed sample amount: 2-3 reference wafers for pre-measurements, 2-3 SisuSemi treated wafers for post-measurements.

Feasibility – wafers

- Integrate SisuSemi solution into a critical process step.

- Demonstrate yield and performance improvement.

- KPIs: Component performance, chip-to-chip variation, yield.

- Proposed sample amount: Starting from 5 wafers for treatment (+ control wafers), or at least 1 wafer per recipe if multiple recipes are studied.

Project Plan

Agree on scope, timeline, cost, objectives, and KPIs.

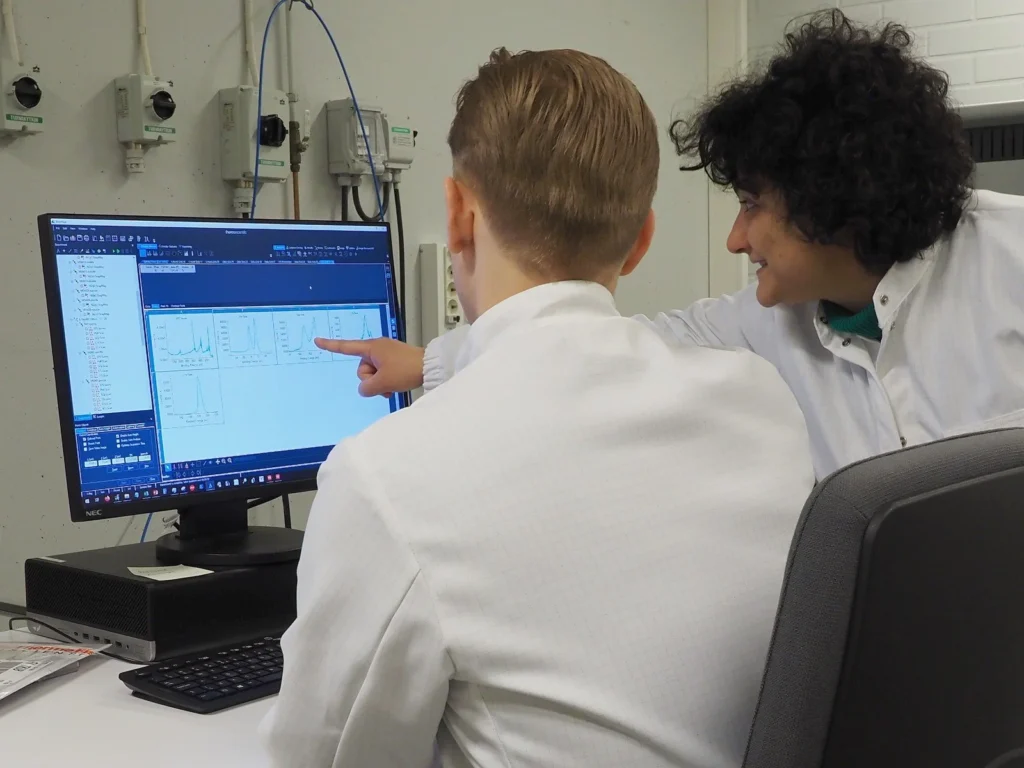

Pre-measurements

Measure samples before treatment.

If preferred, we can continue straight to analysis and insights after this stage.

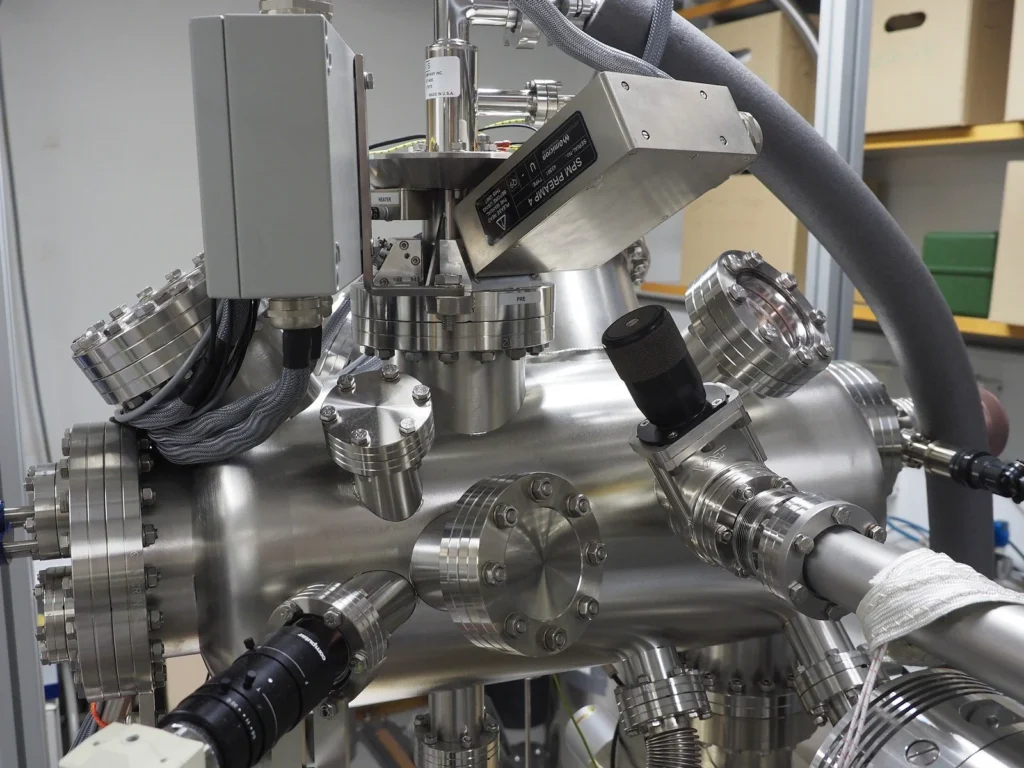

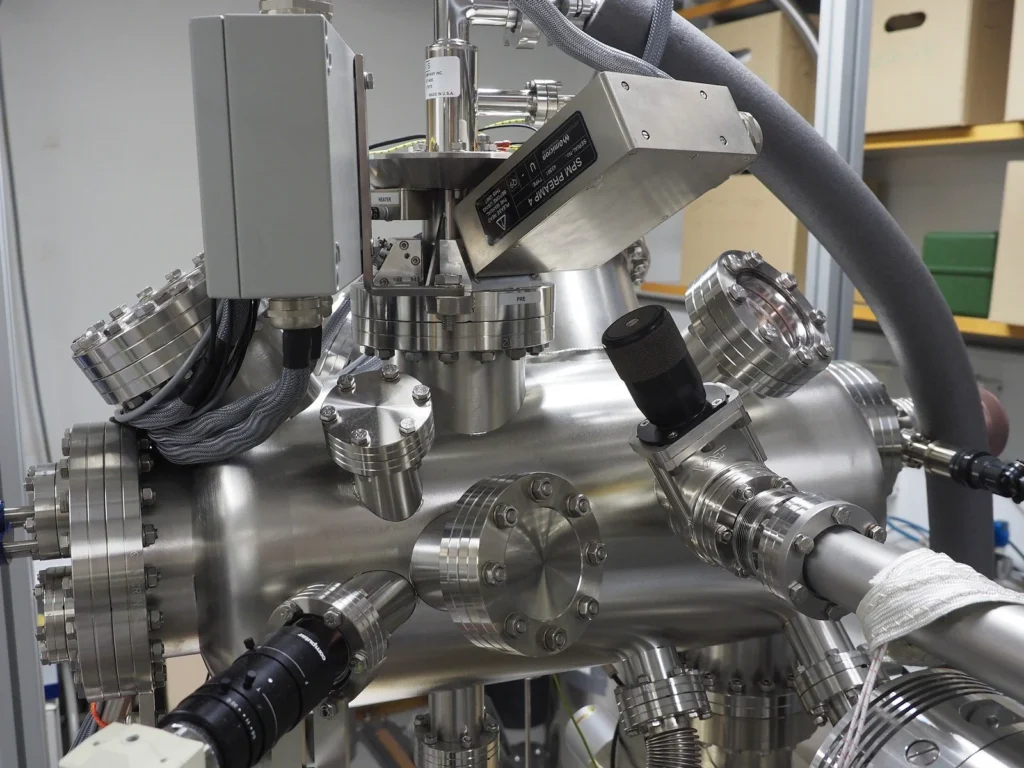

SIsuSemi Treatment

Clean and passivate surfaces of wafers and components.

Post-measurements

Measure improvements e.g. in surface quality and leakage current.

Analysis and Insights

Analyze data to identify impurities and improvement potential.

Samples to Customer

Continue the process at your facility.